The Concentrator Photovoltaic Technology (CPV) is considered a promising alternative option to PV-flat solutions to overcome the present day barriers in terms of material shortage and costs, especially if it is declined to high concentration factor values HCPV (High Concentration Photovoltaic). The technology can assure rapid manufacturing capacity scale-up. In fact a single wafer of HCPV cells can supply up to 1.0÷1.5 kWp or more. As a matter of fact existing manufacturing capacity of semiconductor companies is more than sufficient to supply projected 100GWp/year of solar cell production without extra efforts in dramatically reducing thickness of the materials or in searching disruptive technical solution in order to meet the increasing request of semiconductor.

Last but not least the trend in modern mass-product manufacturing is to make a product as recyclable as possible. The main components of PV Concentrator systems are composed mainly of easily recyclable materials: steel, aluminium and plastic that can be easily divided each from the other and it uses less toxic material then thin film technologies such as cadmium, etc.

The CPV technology is also the only option to have PV system’s efficiency greater than 20%. This increases the power density (producible KWh/m2) and it reduces land utilization as well as area related costs. PV Concentration contributes to realise the Implementation Plan (2010-2012) and the Technology Roadmap (2010-2020) of the Solar Europe Industrial Initiative. On other hand the technology will acquire wider market share when it will demonstrate increased reliability and will achieve manufacturing economies of scale, these being actually the main barriers for CPV systems.

In order to enable large-volume production of the CPV systems and reduce their costs, it is necessary to improve the level of integration of the manufacturing of different system components by way of highly automated, high-yield, high-throughput manufacturing processes, from the preparation of the solar cells and the optics to the module and system assembly. Extra effort should be set to the electronics for power control and in-line monitoring.

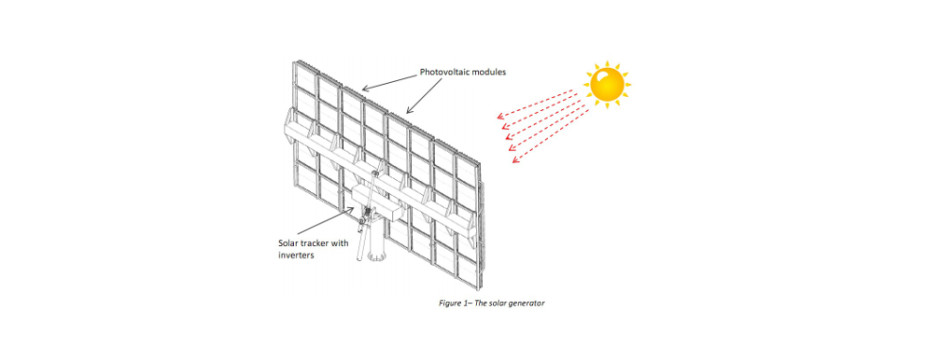

The focus of the project is the design, the development, the realization and the testing of a complete reliable and cost-effective high concentration photovoltaic generator to overcome the barriers delaying the massive introduction of CPV systems. ECOSOLE regards the realization and demonstration of a high concentration photovoltaic generator made of:

The focus of the project is the design, the development, the realization and the testing of a complete reliable and cost-effective high concentration photovoltaic generator to overcome the barriers delaying the massive introduction of CPV systems. ECOSOLE regards the realization and demonstration of a high concentration photovoltaic generator made of:

– A set of very simple but high efficiency PV (PhotoVoltaic) modules by using high efficiency concentrators and III-V solar cells;

– An improved module housing can be easily realized at low cost and with very high throughput;

– New materials and realization procedures in order to assure improved reliability and easy recycling of the CPV generator components after the utilization cycle;

– A set of high efficiency DC-AC converters for the injection of the energy into the electric power grid;

– A low cost high precision solar tracker that will demonstrate the optimization of one of the weak chains of the CPV technology.